72,000 euros. That’s what it costs when a chip-producing device breaks down for an hour owing to a malfunction. It is really logical that organizations want to reduce these forms of breakdowns at all fees. Their resolution is preventive servicing: detecting potential problems in time, so that they can intervene ahead of it is also late. Predicting the ideal time for routine maintenance (not far too late, but not way too early possibly) having said that is not straightforward, especially as every piece of equipment is diverse. Ph.D. researcher Collin Drent located the respond to to this problem in sensible mathematical versions and data—lots of data. He a short while ago received his Ph.D. with honors from the section of Arithmetic and Pc Science.

Chip devices are not the only superior-tech devices whose failure can costs handfuls of cash (and from time to time even lives). Consider of trains or planes, CT scanners in hospitals or wind turbines at sea. It is believed that unplanned machine failures value companies worldwide all around 50 billion euros each yr. About 50 percent of this is because of to breakdowns. A significant amount of money, in other text.

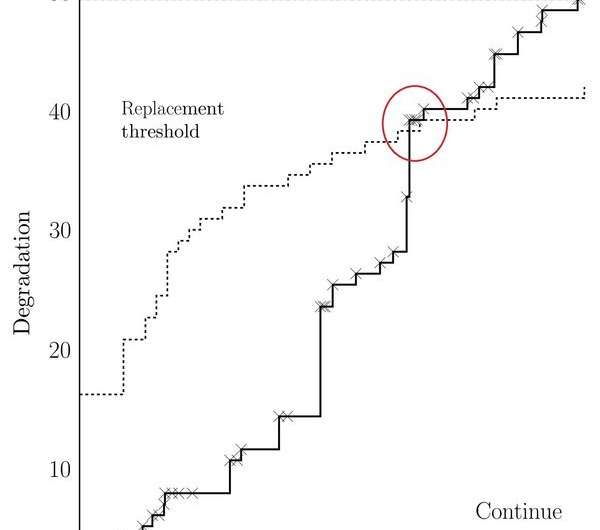

“It is hence critical for firms to detect possible failures of essential parts in time, so that they can mend or change them in advance of it is much too late,” suggests Collin Drent, a researcher in the Stochastic Functions Research team. “But of course, corporations also do not want to intervene also early: areas are high-priced, and you’d want to use them for as extensive as feasible.”

An costly scanner

To figure out the ideal time to intervene, Drent investigated Philips’ so-referred to as IXR scanner. These high priced CT scanners permit medical doctors to complete picture-guided surgical treatment that is minimally invasive to the affected individual.

Drent swiftly observed out throughout his research that the normal designs for preventive routine maintenance do not get the job done very well in this scenario. “They think that products are all the identical, and that you can as a result predict with fantastic certainty when certain components need to have to be replaced. But which is normally not accurate. Each and every CT scanner is various, and so is the way and location wherever it is employed. Consider about the temperature or humidity.”

Fortunately, these present day gadgets, due to the fact of the a lot of sensors they are equipped with, produce an terrible lot of info. “We can use this details to make our models smarter and smarter. In this way we are capable to make certain predictions for each product and ingredient, even however we will not know in progress exactly which things will impact the getting older system.”

Drent made use of two distinct techniques for his assessment: Bayesian Finding out and the Markov conclusion design. “This has two positive aspects: by combining the understanding ability of Bayesian Mastering with the Markov selection design, I was able to make my predictions even extra exact. In addition, these algorithms are pretty transparent. So we know just what is occurring and for what motive. In that respect, these algorithms complement classic AI solutions these kinds of as deep understanding, wherever the correct workings continue being hidden in a black box.”

In the conclude, the researcher managed to reduce the routine maintenance costs of the IXR devices by about 10 to 20 % on normal, as opposed to typical models. “And which is really a large amount, if you look at how much dollars goes into retaining this sort of higher-tech products: the upkeep fees of this kind of machines are commonly at minimum as superior as the purchase expenses.”

Twins

Drent (28) was explained to all through the marketing ceremony that he experienced been awarded his Ph.D. cum laude. “That came as a total shock to me, but my supervisors afterwards instructed me that it was mainly thanks to my contribution to the field and the wide applicability of my strategy.”

In addition to CT scanners, he seemed at 5 other scenarios. This showed that his products also get the job done in principle for wind turbines and chip devices, for case in point. Drent therefore phone calls his model a “unified framework.”

Though a lot of his research is mathematical, the researcher is at first an industrial engineer. And that is the area where he will return soon after his doctorate. At the conclude of August Drent will start working as an assistant professor at the Operations Scheduling Accounting & Handle study team in the department of Industrial Engineering & Innovation Sciences.

There he will be part of his (identical) twin brother Melvin, who has also lately begun operating as an assistant professor in the OPAC group. Is that a coincidence? “Not really. My brother and I have generally experienced the exact same interests. And we can also function incredibly well collectively. So I’m genuinely hunting forward to my new occupation.”

Structured Learning and Choice Producing for Upkeep. pure.tue.nl/ws/portalfiles/por … 0220701_Drent_hf.pdf

Citation:

New preventive upkeep design can save corporations millions (2022, July 15)

retrieved 16 July 2022

from https://techxplore.com/news/2022-07-maintenance-providers-thousands and thousands.html

This doc is subject matter to copyright. Aside from any good working for the function of non-public review or investigation, no

element could be reproduced with out the written permission. The content is offered for facts functions only.

More Stories

Indulge in Luxury: High-End Women’s Cardigans Worth It

History of the Computer – Cooling, Part 1 of 2

The Importance of Video and Computer Games